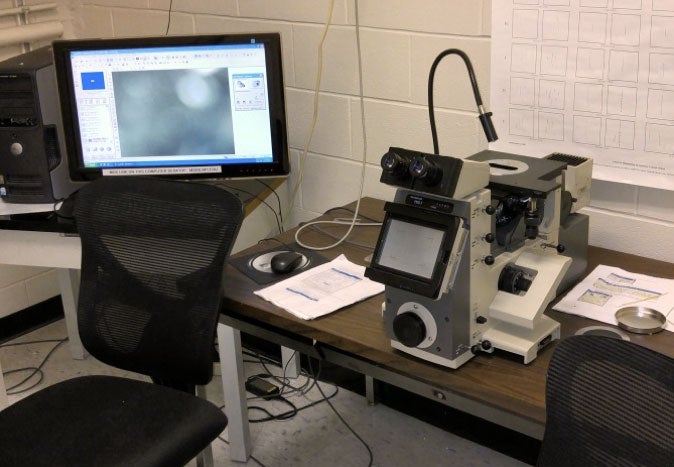

Metallography involves the preparation and examination of specimens for their microscopic structure which determines their bulk physical properties. Despite its name, metallographic methods can be applied to ceramics, glasses, polymers and biological materials as well as metals. Preparation typically involves sectioning, mounting in various polymer systems, grinding and polishing to a mirror surface, chemical or electro etching of the surfaces, optical or electron microscopy, and micro or nano indentation hardness testing. Macro hardness testing is also carried out in the Metallographic lab.

Preparation of samples using various media including SiC, alumina, cerium oxide, silica, or diamond

Preparation of samples using various media including SiC, alumina, cerium oxide, silica, or diamond

Obtains micro-photographs and measures features sizes

Digital Rockwell macro hardness tester and a micro-indentation hardness tester for Knoop or micro Vickers.

Surface grinder

Machine shop with a drill press, various cutting machines and grinders

mounted and polished specimens.