Metallurgical research at Rensselaer spans development and processing of advanced alloys for structural and aerospace applications, to interconnects and contacts for electronic technologies, in addition to fundamental studies of their degradation and corrosion mechanisms. This research combines strengths in advanced characterization techniques and predictive computational simulations to uncover the dependence of microstructure on composition, growth and processing techniques, its effect on mechanical properties and chemical stability, as well as to actively control it to target desired properties.

Engineering microstructures of metals and alloys depends critically on quantitative understanding of nucleation and solidification. This involves experimental characterization of microstructure, mechanical, thermal and electrical properties using electron microscopy, differential thermal analysis, electrodeposition and directional solidification studies, coupled closely with computational modeling using phase field methods. Present focus areas for microstructural design include aluminum alloys for mechanical properties, and lead-free solders such as Sn-Ag-Cu alloys for electrical contacts.

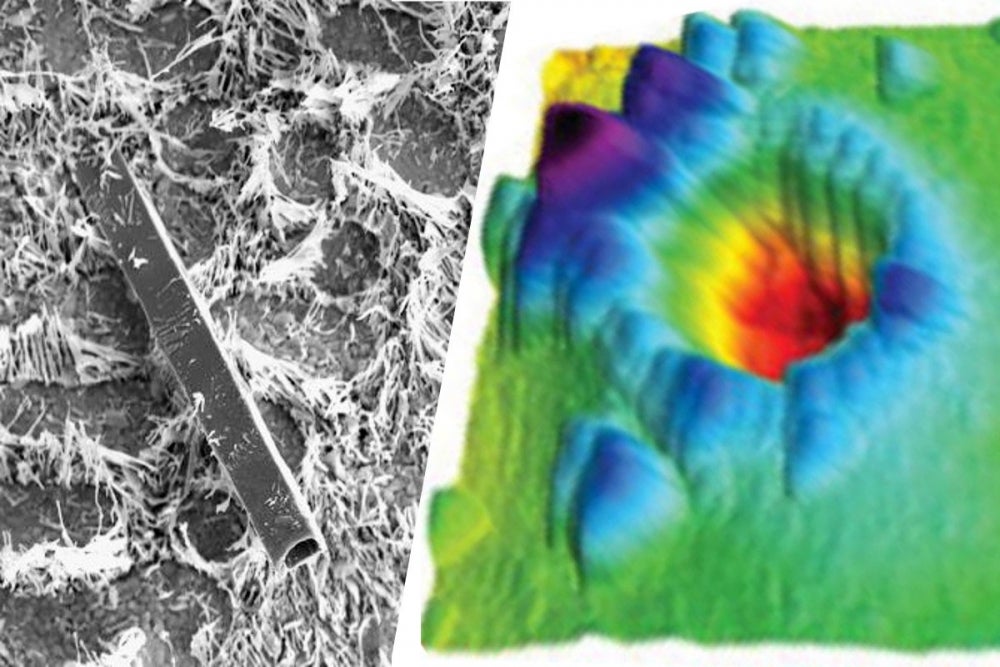

Chemical stability, corrosion and degradation are key concerns for metallic materials, which become increasingly important at reduced nanoscale dimensions in new technologies. Advanced characterization tools such as in situ electron microscopy combined with electrochemical measurements enable investigation of fundamental nanoscale mechanisms of corrosion of materials and solid-state electrode degradation in batteries. Corrosion research at Rensselaer also extends beyond metals to ferroelectric materials under extreme conditions of low pH, high pressures, and high temperatures for applications in oil and gas exploration.